Brown Sugar

The Source Itself

While it is true that sugar can be made from other sources (like beets, for instance), all “cane” sugars come from sugarcane, and that includes every sugar made by C&H®. The sugarcane plant is actually a type of grass that grows rapidly and efficiently to produce sucrose, the ingredient that makes all cane sugars sweet, as well as the molasses. And it is the molasses content that sets C&H® Light Brown Sugar and C&H® Dark Brown Sugar apart.

Our sugar comes from sugarcane, pressed to release its coveted sweet cane juice, that is then crystallized into raw sugar. From there, our experts with decades of experience are able to turn this into an array of delicious C&H® Sugar products by crafting each batch to the highest standards.

Sugarcane is a “C4” plant capable of efficiently removing CO2 from the atmosphere.

While just 3% of plants on Earth are labeled “C4,” this vegetation is responsible for 25% of all CO2 fixation.

Where the Color Comes From

White granulated sugar is what most people think of as “sugar,” but in actuality, it takes a lot of effort to turn sugarcane into those pure, white crystals. The juice extracted from sugarcane is filtered, separated and purified until only sucrose remains. Brown sugars offer more color and more complex flavor profiles. The amount of molasses that is kept in the final product is what separates white, light and dark brown sugars from each other, in terms of their color, moisture and taste.

A single stalk of sugarcane contains 30 tsp. of sugar, 6 tsp. of molasses, 1 qt. of water and 6 oz. of plant fiber also known as “bagasse.”

The best part is that all these ingredients can be put to good use, either in the final product itself or, in the case of the extracted water and bagasse, as reclaimed resources to be used during the sugar-making process.

Making the Most of Molasses

Molasses is a thick, dark and sticky syrup that comes naturally from sugarcane and is made up of sugar, water and compounds from the stalk itself. When the sugarcane juice is extracted and separated, the richest, most complex part of it is evaporated and concentrated into molasses. Depending on how the sugar process is crafted determines how much of this rich ingredient, molasses, remains in the final product which in turn determines whether it becomes C&H® Dark Brown Sugar (the most molasses), C&H® Light Brown Sugar (some molasses), C&H® Turbinado Sugar (slightly less molasses), or C&H® Organic Raw Cane Sugar (least amount of molasses).

The molasses we eat comes only from sugarcane

Only sugarcane molasses is used to make brown sugar whether the sugar comes from sugarcane or beets. This is because the molasses from beets has different flavors and consistencies.

Taking Stock of Taste

The flavors found in molasses are deep, complex and surprisingly varied. The molasses that remains or gets added can have a profound effect on how it tastes. In C&H® Light Brown Sugar, the smaller amounts of molasses give subtle hints of caramel and even vanilla flavor. When you use C&H® Dark Brown Sugar, spiced flavors and even chocolate can be tasted. In the hands of our experts, molasses is an integral part of how we make high-quality sugars capable of creating a world of cuisine.

The flavor compounds in molasses are referred to as “ash,” though they bear no resemblance to the ash from a fire.

Instead, much like a fine wine, these trace amounts of minerals come from the soil composition of the area in which the sugarcane was farmed and help to make the taste profile of molasses from one region distinct from that in another.

Moisture Makes an Impression

In addition to adding sweetness and flavor, the use of brown sugars in a recipe helps in other ways. Much of this has to do with how these dynamic products deal with moisture. Since sugar is hygroscopic, meaning that it attracts and absorbs water, it aids in keeping freshly baked cookies and cakes moist and delicious. And because the tiny amounts of water it traps are stored in the sugar itself, there is less free water in baked goods that might allow mold or bacteria to form. That means sugar helps with texture and preservation as well, adding to the list of things we have the sugarcane plant to thank for.

During refining, “invert” sugar is formed.

This thick, sticky syrup is created when sucrose breaks down into glucose and fructose, and is responsible for the hygroscopic nature of sugar itself.

Benefits as Clear as Crystal

When you look closely, even microscopically, at sugar, you can see many of its attributes even before you taste them. The molasses that gets trapped in or on the crystals adds flavor and color. This determines whether the sugar is hard, dry and free-flowing, or if will be soft, sticky and more likely to clump. The difference in the size of sugar crystals adds other possibilities for cooks and bakers as well. This lets them regulate the appearance and texture of various items, and even to control how slowly sugar dissolves into items like iced coffee or tea—allowing them to release their sweetness over time.

Larger crystals are drier, while smaller ones help retain moisture.

This might seem counter-intuitive, but a larger number of smaller crystals actually has more surface area that can trap moisture than a smaller number of larger crystals, even if the amount – say, 1 cup – is the same.

Thank you for taking the time to learn where our brown sugars come from, how they differ and how they can sweeten your next recipe. We know that when you mix family, friends and food made with C&H® Sugar, you create magical moments and memories you’ll never forget. In other words— The Recipe for Happiness Starts With C&H®.

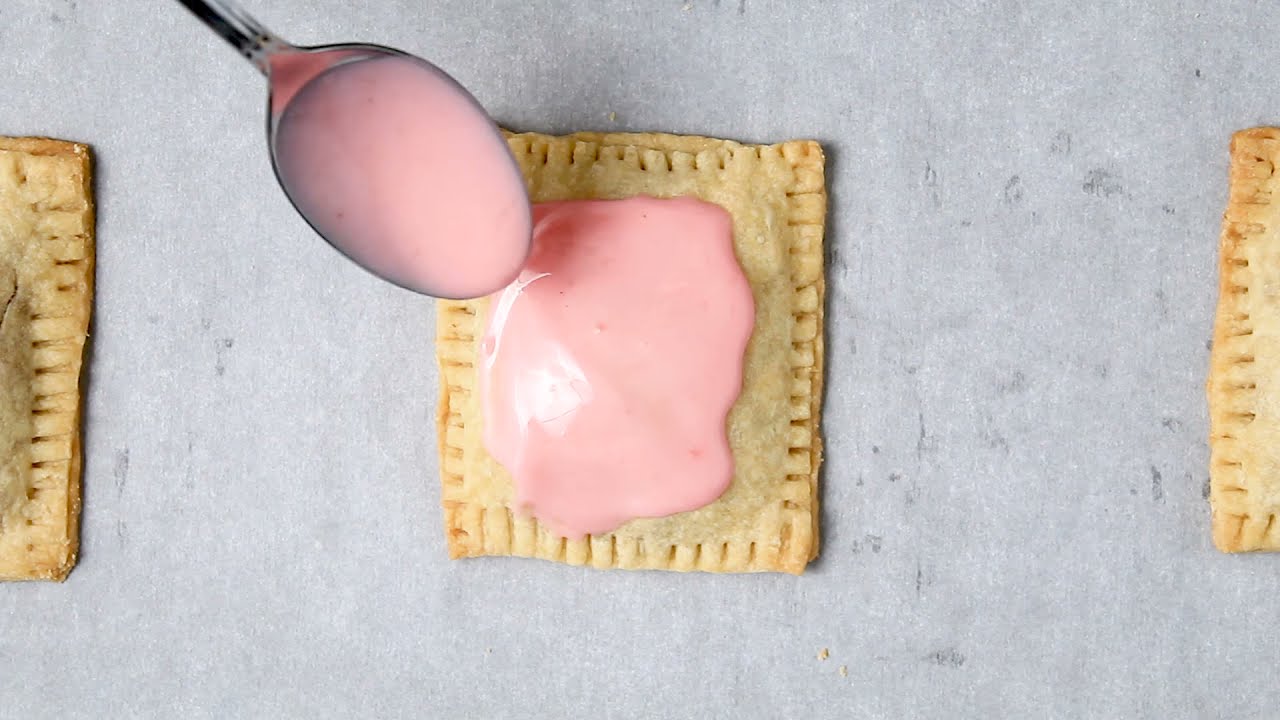

Enhance Your Favorite Recipes With C&H® Dark Brown Sugar

Ready to take your recipes up a notch? Try mixing in the deep, rich flavor of C&H® Dark Brown Sugar. Its delightful molasses taste is great for flavorsome desserts and sweet dishes of all kinds. From decadent brownies and pies to delicious pancakes and syrups, you’ll add a little pizzazz to everything you make in your kitchen.

Discover Recipes